DiaInspect DLM

Automated Particle Analyzer

DiaInspect DLM is an automated particle analyzer tailored for large-scale size and shape analysis of superabrasives in production. It features cutting-edge optics and lighting components that produce a distinct diffuse backlight.

Diffuse Light Microscope.

Fully Automated.

Advanced optics and lighting components allow the use of white diffuse backlight for both moving and stationary particles. The device provides consistent information on powders using a representative sample size. It measures the numerical distributions of size and shape parameters, which serve as characteristic properties of specific products.

Its advanced technology ensures precise, consistent measurements and efficient throughput, making it an ideal choice for quality control and process optimization. With its robust construction and user-friendly interface, DiaInspect DLM seamlessly integrates into existing production lines to enhance productivity and maintain high standards of quality.

For documentation, images of individual particles are stored in a collection. The collection’s resolution is automatically adjusted for particle images between 100 and 120 pixels in width.

Operating Principle

Particles are transported on a rotating plate into the microscope. Once analyzed, the particles are drawn into a collection box.

The system captures and evaluates images of each recognized particle, allowing for the inspection of a large number of individual particles. With a grain size of 400 um, up to 5,000 particles can be analyzed per minute.

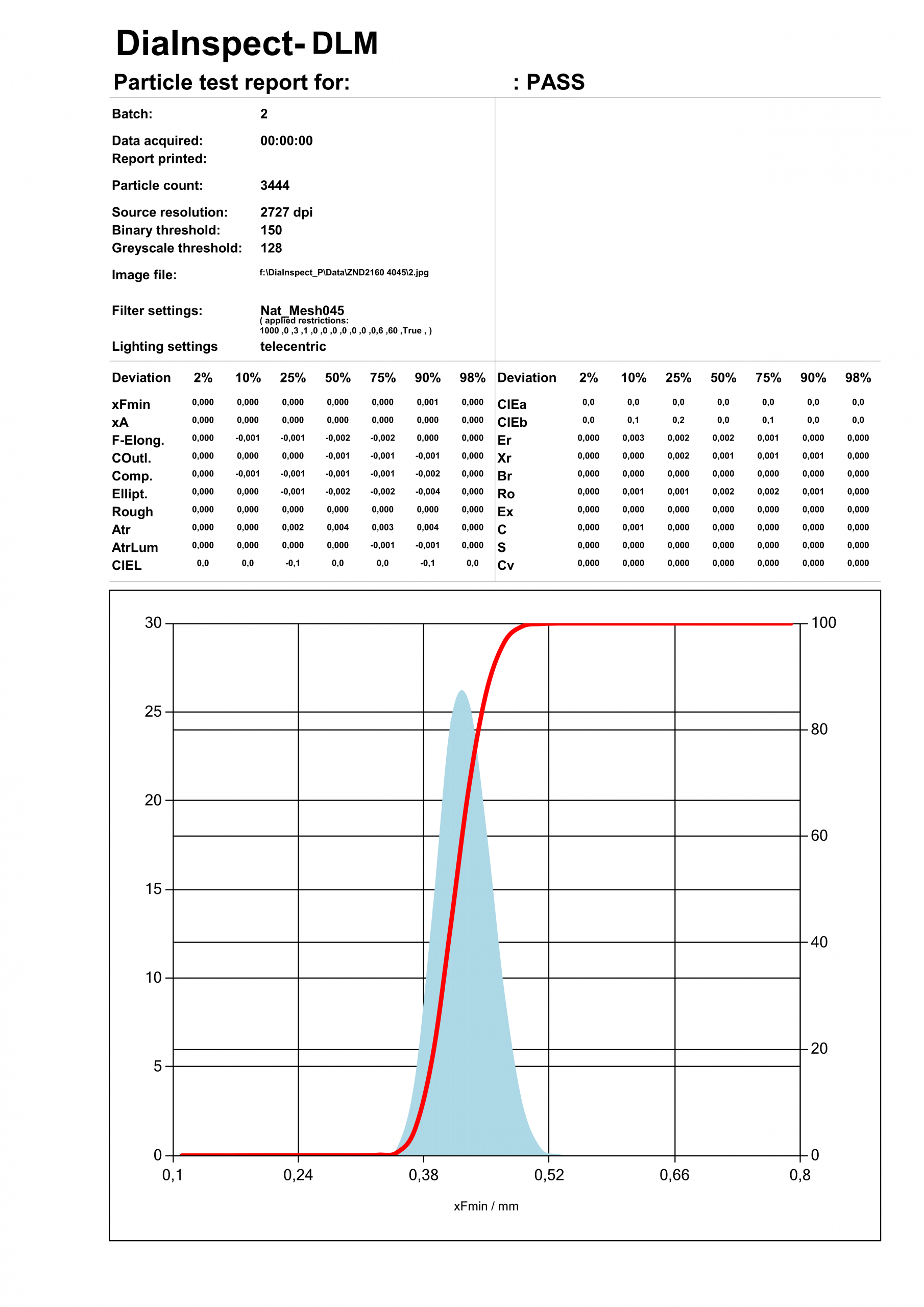

After the measurement, the system automatically generates a report.

Operating Concept

The operating concept of DiaInspect DLM follows standard operating procedures (SOPs), stored as definitions of machine actions and settings tailored for processing a specific product. In DiaInspect DLM, each commercial grain size is treated as a distinct product.

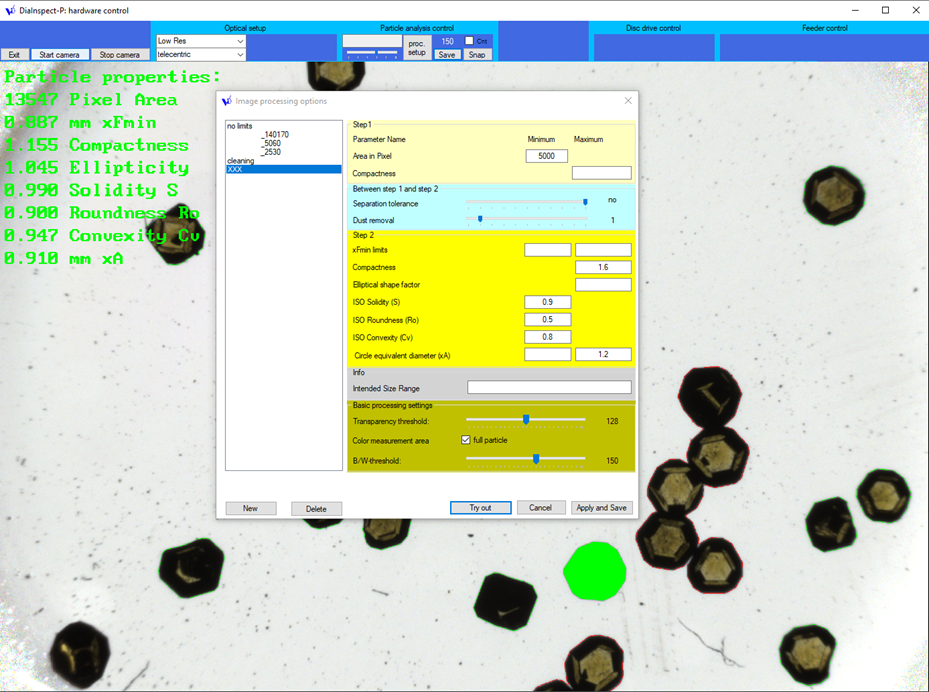

The hardware can be manually operated to determine optimal machine settings for each product. Once the ideal settings are established, a product profile can be created based on these parameters. The program then generates a dedicated folder for the product and records all measurement results for the product in this folder.

The parameter distributions of the tested batch are automatically compared to the product’s tolerance band.

System Interface

The system’s operation is managed through a user-friendly program interface that operates on a standard PC.

This interface allows users to easily navigate through different functions and settings, making it simple to control and monitor the system. With clear icons and intuitive menus, users can quickly access the information they need and make adjustments as necessary.

The control program enables pausing the measurement process at any point. Data collected is saved on the hard drive and can be retrieved at a later time when the operator decides to resume the task.

Parameters

Extract from the list of calculated parameters for individual particles and the entire batch:

- Minimum feret diameter

- Maximum feret diameter

- Circle equivalent grain diameter

- Total area

- Perimeter

- Convex perimeter

- Moments of inertia

- Feret elongation

- Compactness

- Roughness

- Ellipticity

- Percentage of the „transparent“ appearing area

- Relative brightness of the „transparent“ appearing area

- Colour coordinates in the CIE Lab-system

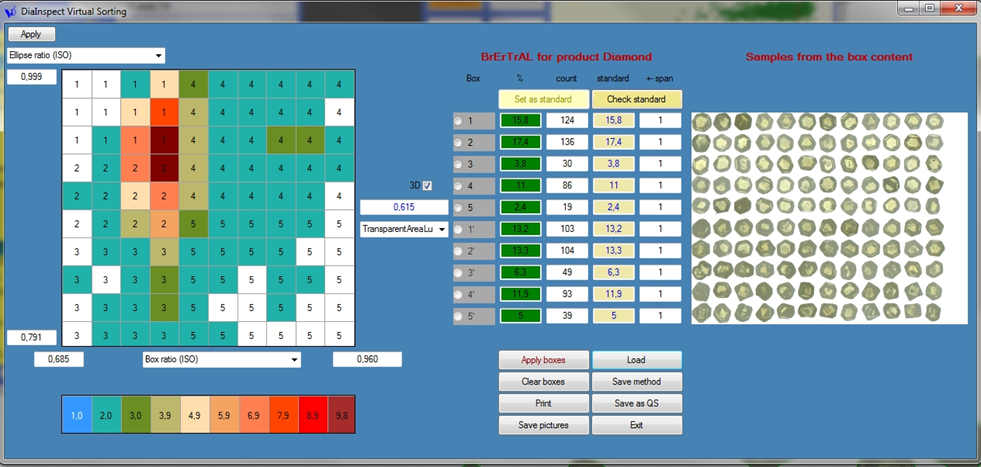

Results

While a standard report is automatically generated, all results are saved in Microsoft Excel file format. Each batch has its own file containing data for every tested particle. There is also a separate file for each product, summarizing the statistical distribution of measured parameters across all batches associated with that product. Printed reports include selectable data for each batch.

These reports can be customized to focus on specific data points or trends, making them a valuable tool for quality control and process optimization. Additionally, these reports can be easily shared across departments to facilitate collaboration and decision-making. The data is stored in a structured manner, enabling efficient retrieval and analysis whenever needed.

Technical Data

| Power supply | 110 … 240 V A.C. |

| Measurement range | Grain size: 100/120 … 8/10 US-mesh |

| Processing time |

app. 2-3 minutes Preparation and test of 5,000 particles (grain size: 400 µm) |

| System |

PC with Windows 11 (64 bit) |

| Camera |

USB 3.0 connection |

|

Required accessories (not included) |

Screen, keyboard, mouse |

| Supported languages |

Chinese, English, German (others upon request) |