DiaHeat v4

Thermal Toughness Index (TTI)

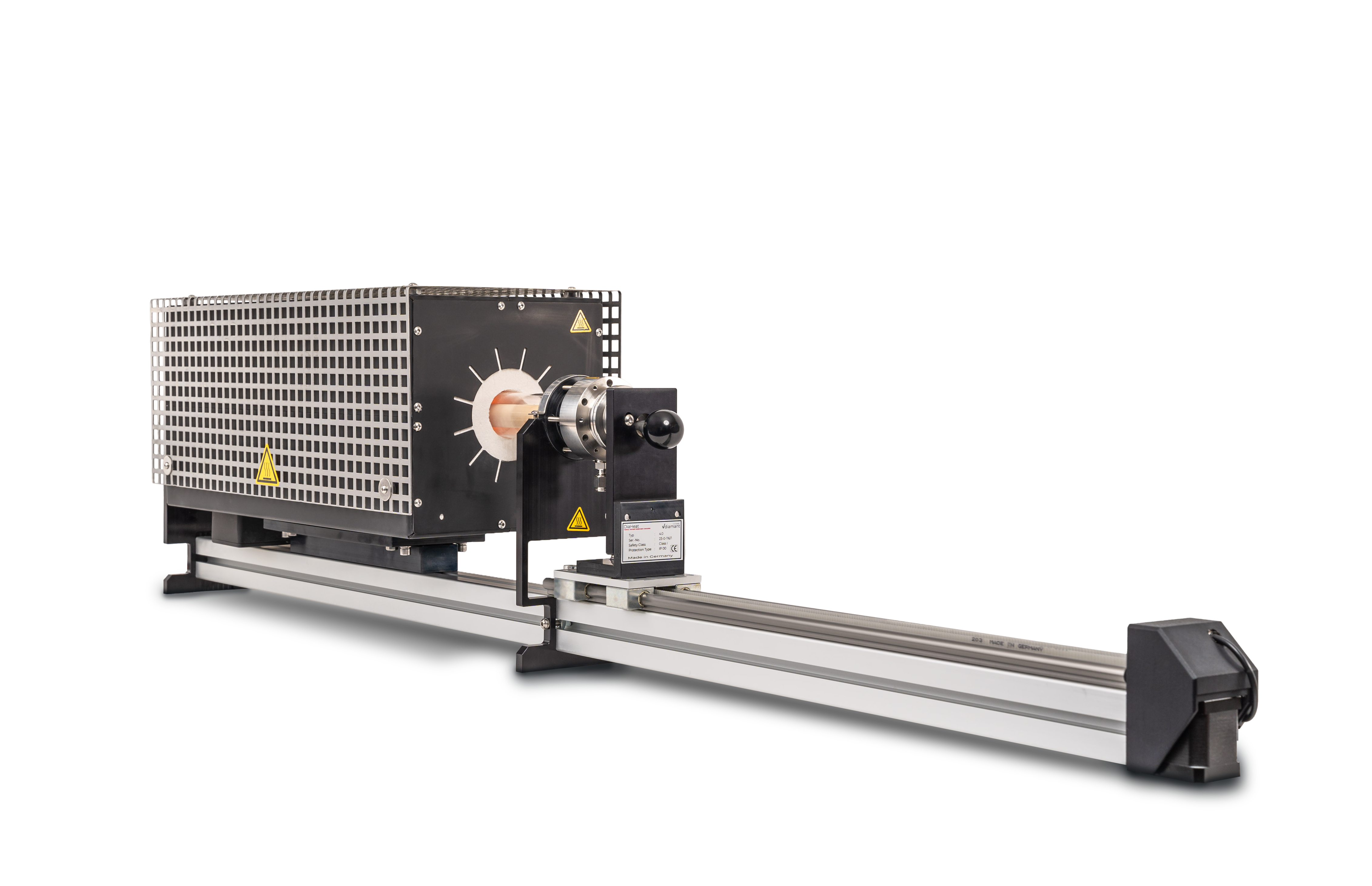

This specialized furnace is designed for the automatic thermal treatment of industrial diamond grit in a protective gas environment, reaching temperatures up to 1,100°C. This is an essential part for accurately measuring the Thermal Toughness Index (TTI).

Version 4.

Freshly Redesigned in 2024.

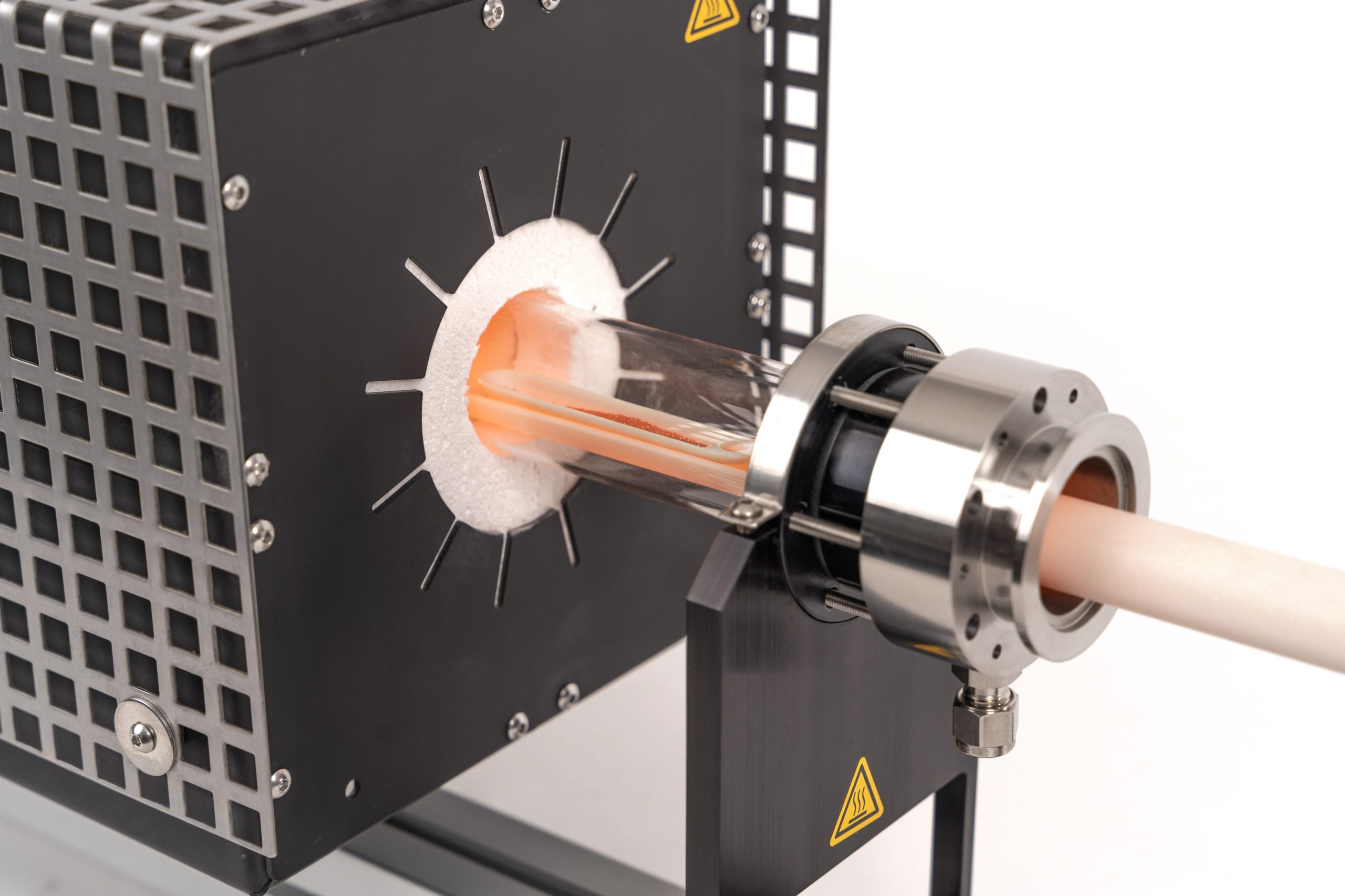

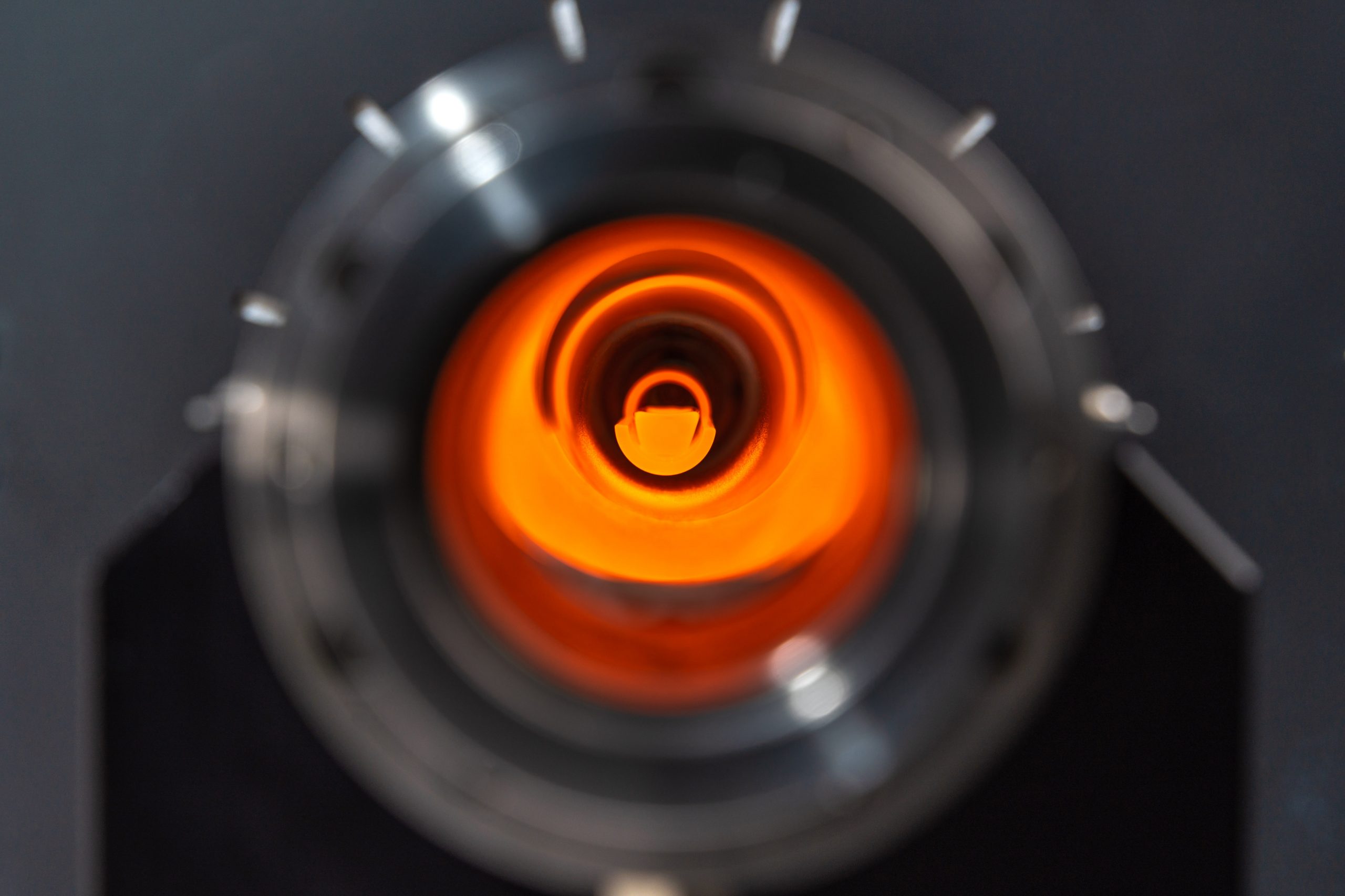

DiaHeat v4 is an automated tube furnace specifically engineered for thermal stress testing of powders. The heater block is constructed for durability under high temperatures, with the heating wire directly attached to the inner surface of the block. This design enables a rapid temperature rise and allows for high operating temperatures without risking wire overheating.

A protective gas flow eliminates oxygen from the furnace’s interior, safeguarding the specimen from oxidation. Two integrated controllers ensure stable, precise temperature maintenance and automated sample processing, providing accurate and reliable performance.

Drop It Like It’s Hot.

Determining the thermal strength of industrial diamonds requires treatment at temperatures between 800°C and 1,100°C under a protective atmosphere. This process is essential for subsequent friability testing (TTI) or single crystal testing (CFF, CFS).

Operating Principle.

First, the heater control is set to the desired working temperature, which is quickly achieved due to the heater’s innovative design. Next, a ceramic dish containing the diamond sample is placed onto the sample holder and the program is initiated. The controller then moves the sample through preheating, heating, and cooling phases for a programmable duration.

This treatment process operates autonomously, ensuring precision and reproducibility without operator intervention. In manual mode, the operator can manually move the sample in and out as needed.

Technical Data

Furnace

| Dimensions | ca. 1,450 x 205 x 320 mm |

| Weight | ca. 15.5 kg (total), ca. 7.5 kg (heater) |

| Length of heated zone |

400 mm |

| Interior diameter |

42 + 1 mm |

| Heating wire |

Kanthal A1l |

|

Heating wire diameter |

1 mm |

| Heating wire electrical resistance |

app. 34 ± 1 Ohm |

| Heating current |

max 6.4 A |

| Heating power |

max. 1.5 kVA |

| Max. temperature |

1,100 °C |

| Continuous working temp. |

1,100 °C |

| Protection class |

IP 20 |

| Max. heat-up rate |

20 K / min. |

| Quartz tube |

Length: 750 mm, Inner diameter: 35 ± 1 mm, Outer diameter: 40 ± 1 mm, Glass type: C611

|

| Protective gas |

Argon (or Nitrogen), up to 5 liters per minute gas flow |

Technical Data

Control Unit

| Dimensions | ca. 280 x 31 x 220 mm |

| Weight | ca. 6 kg |

| Power supply |

230 V, 50 Hz, 16 A or 110 V A.C. |

| Protection class |

IP 30 |

| Temperature controller |

OMRO E5GC |

| Motion controller |

VD-Motion controller |

| Thermocouple | S |