Magnetic Sorter v4

High Precision Sorting. High Throughput.

Our Magnetic Sorter v4 efficiently sorts superhard materials, like synthetic diamond, within an intense magnetic field. Its advanced design ensures precise separation and classification, contributing to enhanced productivity.

Why it’s so Important.

Synthetic diamonds often contain metallic inclusions, which can vary in quantity and typically exhibit ferromagnetic properties. These inclusions affect the thermal and mechanical characteristics of the diamond grains, necessitating their separation into magnetic and non-magnetic fractions.

Therefore, it becomes imperative to segregate the diamonds based on their magnetic and non-magnetic fractions to ensure precise control over their properties and applications.

Innovative. Precise.

And Fast.

The innovative magnetic circuit design enables higher throughput and sorting precision compared to conventional machines. The high magnetic field strength facilitates the sorting of even very low-susceptible material.

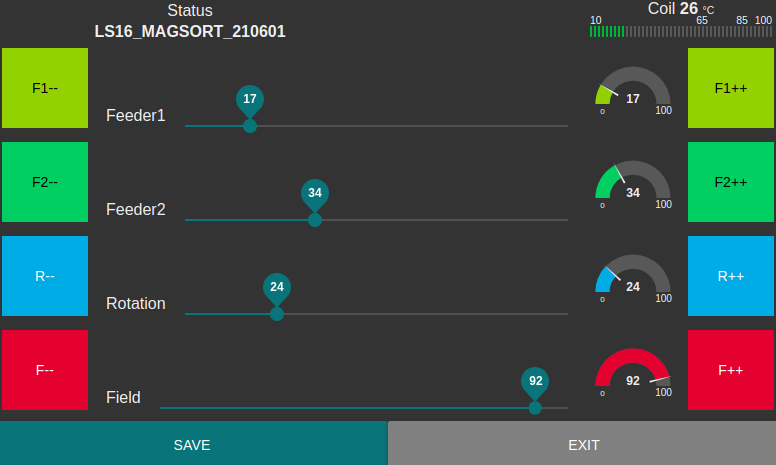

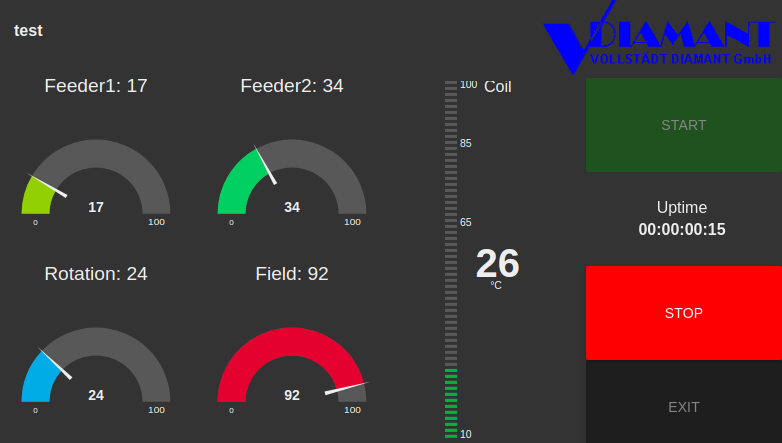

All components of the MagneticSorter v4 are digitally controlled to ensure the utmost reproducibility and stability. The control unit can store and retrieve different sorting programs. With the user-friendly touch-panel control, adjusting the machine for new sorting tasks takes only seconds.

For enhanced customization, we recommend utilizing our measuring device DiaSusz. This enables you to verify sorting results and make adjustments as needed.

Impressive.

How it Works.

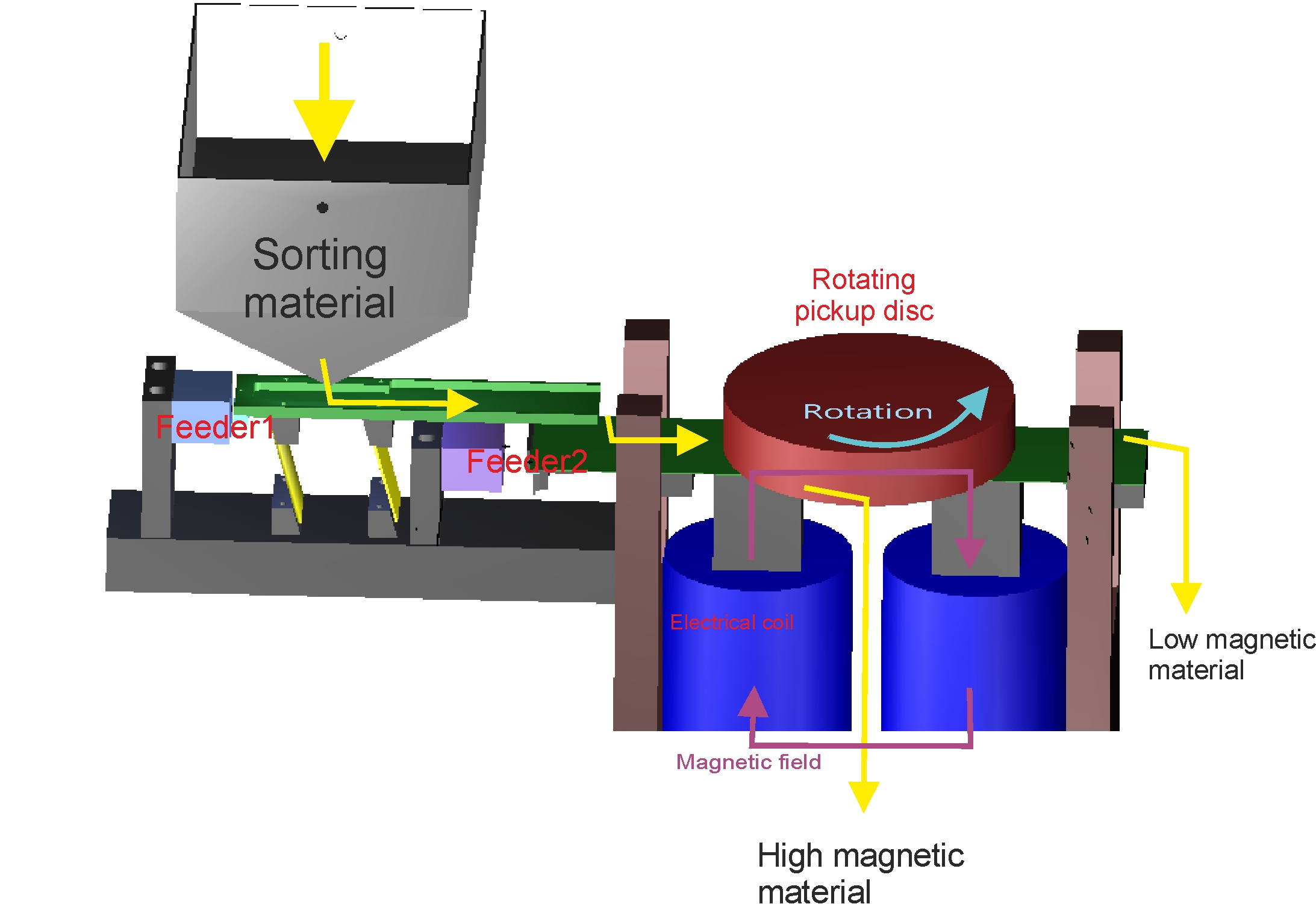

At the heart of the machine lies the sorting gap, where particles undergo magnetization by a powerful magnetic field. Two feeding trays regulate the quantity and velocity of particle flow through the sorting gap. Within this gap, magnetized particles are vertically lifted from the non-magnetic material flow, extracted from the gap, and stored separately. This lift-type operation, coupled with a unique magnetic field design, enables exceptionally precise sorting.

The digital control unit enables precise adjustment of all machine parameters: material flow rate, velocity, magnetic field strength, and disc speed.

Special Features.

- Tablet PC control

- Logging functionality

- Manual or automatic mode

- Simple product database creation

Flexibility.

Manual vs. Automatic.

The Magnetic Sorter v4 can operate in both manual and automatic modes. In manual mode, all parameters can be adjusted freely. In automatic mode, parameters for different materials are saved in product definitions, which can all be used in automatic operation.

The device is controlled using a separate tablet PC. The user-friendly interface allows for easy adjustments and monitoring, providing precise control over the device’s settings and operations.

Technical Data

| Power supply | 230 V, 50/60 Hz, 10 A (100 / 115 V upon request) |

| Operating power |

< 700 W |

| Dimensions |

1200 x 380 x 840 cm |

| Weight |

ca. 140 kg |

| Magnetic induction |

0… ~ 1500 mT (digital adjustment, not calibrated) |

| Pickup-disc Speed |

0…34 rpm (digital adjustment, not calibrated) |

| Feeding Rate |

0…600 g/hour (digital adjustment, not calibrated) |

| Coil temperature |

max. 65 … 68 °C (programmed for machine-specific operation, digitally controlled) |

| Size of material |

max. ~1 mm (other maximum sizees upon request) |